What Are Dowels in Construction? A Comprehensive Guide

Critical Considerations for Dowel Bars in Construction

The dowel bar is a fundamental component pivotal to creating robust, enduring structures in construction and carpentry. So, what are dowels? These cylindrical rods are the unsung heroes: binding concrete slabs, enhancing joint stability, and fortifying the foundations.

Get insights into the myriad aspects, from the materials that shape their strength to the nuanced considerations that determine their effectiveness.

Exploring Different Dowel Varieties

Dowel bars come in a diverse range of materials and sizes, each tailored to specific construction needs. We'll delve into some of the most prevalent configurations:

The Size of Dowel Bars

Another important consideration is that the size of dowel bars can vary. As such, the size suitable for a particular project may be an important factor for project engineers to consider when determining how best to utilize dowel bars.

The Material Used

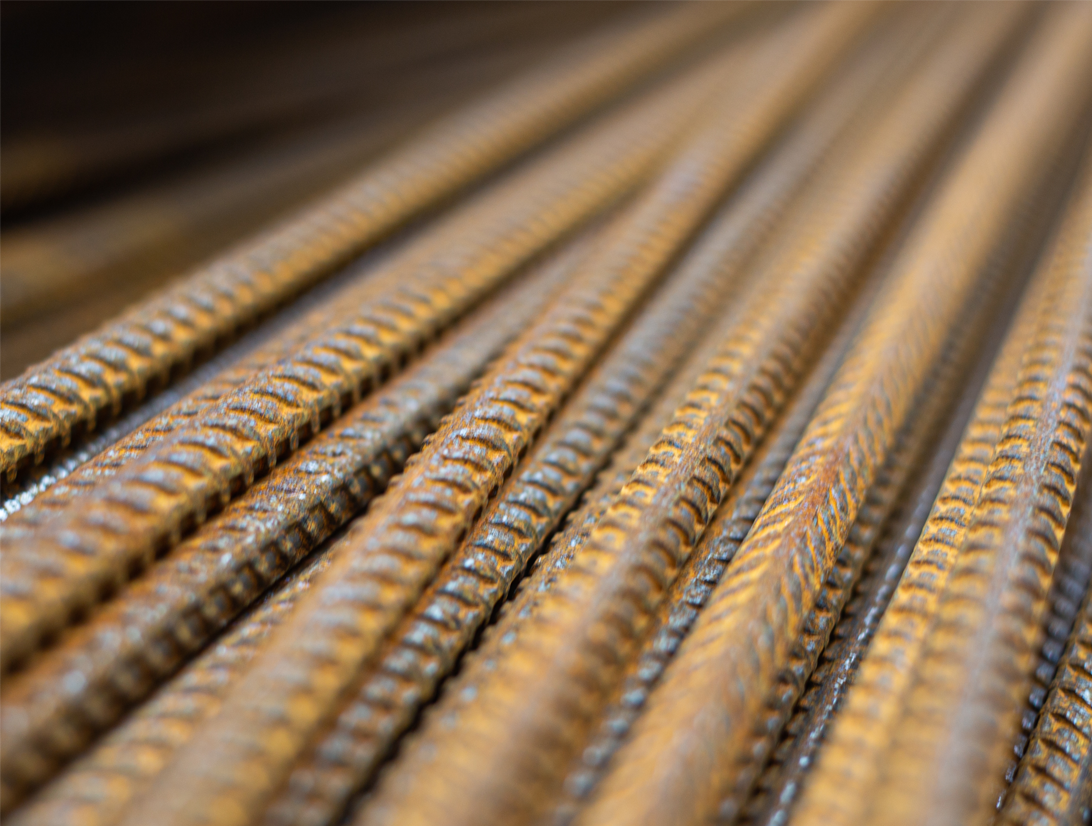

Engineers may consider a range of materials to construct dowel bars, depending on the needs of the project. You may regard some of the options, including stainless steel, epoxy-coated, and glass fiber-reinforced polymer. Which material is most suitable may depend on the environmental conditions around the project—such as the amount of moisture expected. Some of the most common materials include:

Wood

Wooden dowels play a pivotal role in woodworking and carpentry. They are typically crafted from sturdy wood materials like oak, birch, or maple.

We commonly use them to secure the joints in chairs, tables, cabinets, and other furniture pieces. They provide structural stability while maintaining the integrity of the design. Unlike their metal counterparts, the bars made with wood enhance joints between different wooden pieces.

They are relatively easy to work with, allowing craftsmen to create strong, sturdy joints without the need for complex tools or techniques. You can easily cut and shape the wood bars to fit specific woodworking requirements.

Stainless Steel

Stainless steel is generally high-strength and highly corrosion-resistant. It makes a suitable material since it resists the corrosive conditions often associated with concrete. Which naturally possess a low PH and experience exposure to moisture and temperature changes.

Epoxy-Coated

Epoxy-coated dowel bars are another common material. These bars made from carbon steel are high-strength materials, but they lack the corrosion-resistant properties of stainless steel. Epoxy-coated have strong corrosion resistance, making them ideal for situations where corrosion is a big concern.

Glass Fiber

Some dowels made from glass fiber-reinforced polymer can transfer load between concrete slabs in a relatively novel method. This high-strength form of fiberglass is relatively impervious to corrosion and may represent a viable option for applications where long-term corrosion resistance is a particularly critical consideration.

Load Transfer

Notably, the primary functionality of dowel bars is load transfer between concrete slabs. The weight loads on concrete slabs can vary, and if adjacent slabs aren’t secured together or sharing the loads, they can shift and become damaged. This can lead to damage, such as cracks around the edges of slabs.

Stable Joints

Dowel bars also have a critical role in ensuring that the joints where multiple adjacent slabs of concrete come together remain stable. They restrict vertical movement between slabs but enable some level of horizontal shifting, given their shape. Sometimes this means making for a stronger joint.

This enables them to act as a point of lubrication, so to speak, between concrete slabs at horizontal joints. As concrete heats and cools, it can shift, expand, and contract significantly. That’s one of the reasons why dowel bars can be so important in fostering stable joints. Additionally, the use of high-quality dowel caps can enhance their ability to weather the expansion of concrete.

Edge Strength

Dowel bars can enhance the individual slabs into which they're embedded in addition to joining them. Dowel bars can strengthen the edges and corners of concrete slabs, keeping them from being flexible enough around the edges to crack and break as easily.

Important Considerations

There are a number of important considerations when determining how and when to use dowel bars. Dowel bars are an important component in many construction projects involving concrete slabs, but some factors must be considered.

In concrete working, dowel bars serve a range of important purposes. For one, they facilitate more efficient load transfer between slabs. They can help strengthen joints and reinforce slabs' edges and corners. It's important to talk to an experienced engineer for guidance.

Here are some of the factors that may be relevant:

The Placement of Dowel Bars

Where dowel bars are placed can be a crucial consideration in their use. The spacing and alignment of dowel bars are both critical factors in their success. The Concrete Pavement Technology Program, managed by the Federal Highway Administration, for example, offers some Best Practices in Dowel Placement Tolerances.

Dowel Bars Wisdom for Durability

Dowel bars are important in creating high-strength foundational and pavement joints between adjacent concrete slabs. They provide stability and allow nearby concrete slabs to move safely over time. Additionally, they have the ability to strengthen the concrete slabs they are embedded in.

Consult with an experienced professional in order to determine how to utilize dowels for a specific project, as dowels are certainly often crucial part of concrete work.

Don’t forget—if you’re looking for high-quality products for concrete work, including forming accessories and dowel caps, be sure to reach out to Deslauriers today. At Deslauriers, we offer a wide range of solutions to meet your unique construction needs. To learn more, contact us today.

- Protecting Worksites from Dropped Object Hazards: Essential Tools for Elevated Safety

- 5 Ways to Use the Vers-A-Scoop (Beyond Just Masonry Work)

- Deslauriers: Leading the Way in Sustainable Manufacturing

- 5 mistakes to avoid when using concrete test scoop

- Troubleshooting Common Problems with Air Pressure

- Construction materials

- shims

- shims in construction

- concrete

- construction

- Steel columns

- Building support structures

- Structural design

- Types of steel columns

- H-beams

- I-beams

- Pipe columns

- Box columns

- Steel-concrete composite columns

- Construction projects.

- Concrete Column Form

- Concrete Column Form Rent

- Buy Concrete Column Forms

- Construction temperature control

- Thermostatic technology

- Concrete curing

- Temperature regulation

- Construction equipment

- Advanced curing techniques

- Concrete strength optimization

- Structural integrity

- Construction safety

- Composite wood shims

- construction shims

- durability of composite shims

- Lifting Handle Guide

- Lifting Handle best practices

- Dowel Caps

- Concrete Placement in Construction

- Construction Efficiency

- Concrete Placement in Construction Projects

- sustainable construction

- cost-effective building materials

- sustainable building benefits

- environmental impact

- on-site training

- deslauriers services

- construction training

- Equipment Maintenance

- Testing Equipment Care

- Rust Prevention

- Compression Testing Equipment

- Equipment longevity

- column formwork

- concrete formwork